Packaging remains essential during rapid product movement within the competitive food and beverage market because it protects items while simultaneously reinforcing brands and maintaining regulatory standards. Wrap around labelling stands out among many packaging innovations because it provides both efficient application and versatile usage together with high-impact visual appeal.

What is Wrap Around Labelling?

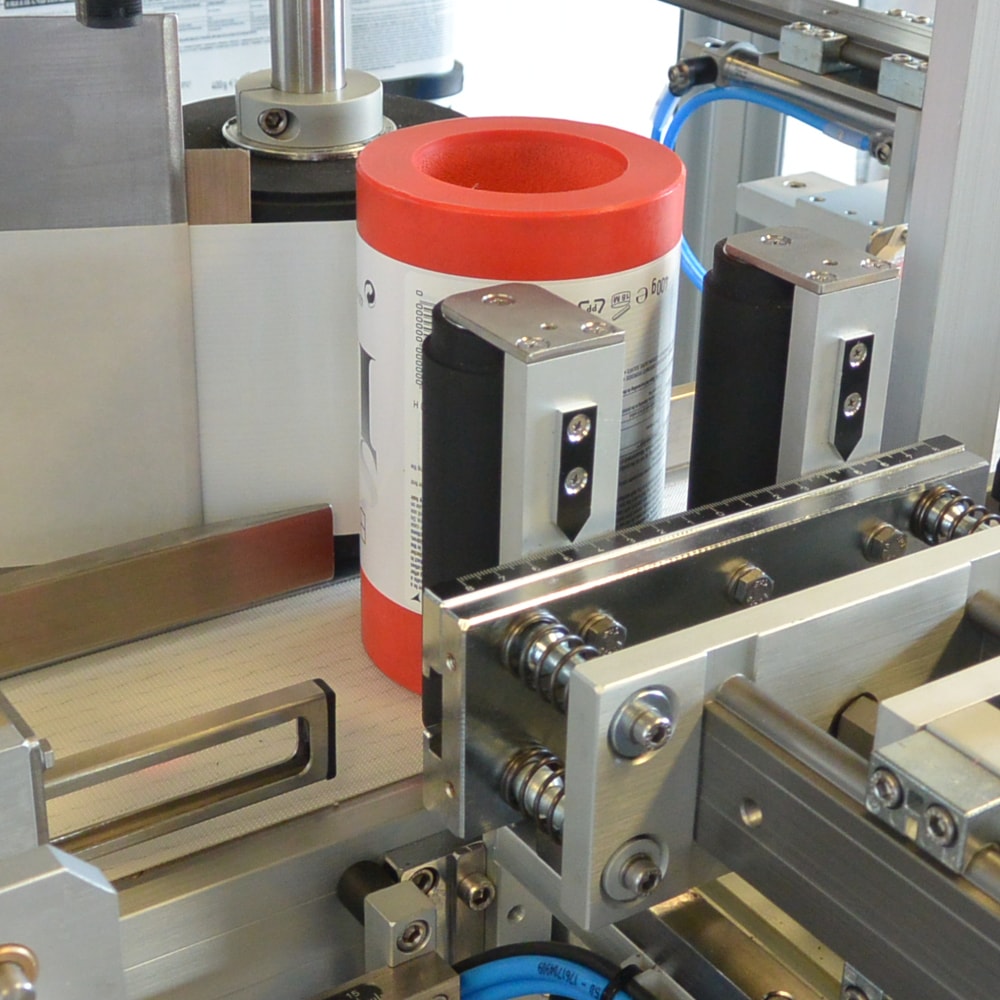

Wrap around labelling represents a packaging solution that envelops product containers fully or partially through circular or bottle-shaped materials. Because they cover the entire perimeter wrap around labels transform ordinary front and back labelling surfaces into multifunctional printing platforms for content and branding elements. Automatic high-speed labelling equipment makes these labels appropriate for high-volume food production operations in the beverage and food industries.

Benefits of Wrap Around Labelling

More communication area becomes attainable with wrap around labelling as a primary benefit. The increased available area permits manufacturers to provide detailed product information without converging important content. A clean and optimized labelling design which stands out on store shelves helps consumers make better purchase choices.

A production facility benefits from wrap around labelling for its improved operational efficiency. Modern labelling equipment operates at fast speeds while maintaining precise label placement which reduces operational downtime together with material waste quantities. The implementation of roll-fed labels enables cost-effectiveness by lowering expenses against traditional cut-and-stack labels while enabling increased production volumes at reduced changeover frequencies.

Applications in the Food and Beverage Industry

The food and beverage sector employs wrap around labelling techniques in all major product categories. This method serves the beverage industry since all beverage bottles from water to juice and soda to alcohol use cylindrical packaging shapes. The labelling style provides benefits to canned goods and dairy containers and sauces alongside condiments. Such flexibility allows wrap around labelling to apply to both hard and flexible package materials.

Beside durability wrap around labels prove essential for food and beverage industry needs. Passive labels endure multiple exposures to refrigeration processes in addition to moisture and handling stresses during transportation through the supply chain. Synthetic material wrap around labels demonstrate exceptional resistance to environmental conditions so products maintain their market-ready state for consumption.

Customization and Design Flexibility

Wrap around labelling provides food and beverage manufacturers with significant design flexibility as their primary benefit. Full-color graphics combined with transparent section elements and unique textures serve as opportunities for brands to design visually powerful packaging formats. A saturated market demands eye-catching packaging to attract customer attention which wrap around labels effectively achieve successfully. The extended continuous label surface enables seamless integration of artwork and messaging which produces both premium and professional visual effects.

Variable data printing capabilities available on the labels eliminate the need for separate production steps which ensures producers can directly embed batch numbers and expiry dates along with promotional codes onto the labels. Production functions more efficiently through this approach that fulfills all required compliance requirements.

Sustainability Considerations

The industry transition toward sustainable practices makes wrap around labelling an eco-friendly option available to producers. A combination of recyclable materials for labels with compatible adhesive formulations for recycling processes results in decreased environmental impacts. Film labels designed for lightweight applications reduce packaging weight which results in decreased transportation emissions along with enhanced sustainability performance.

Conclusion

The food and beverage sector benefits from wrap around labelling systems because these solutions combine pragmatic design with effective results. The solution enables better product visibility while it can hold vast amounts of information while working well in high-speed production systems. Sustainably designed and versatile wrap around labelling remains a top choice among producers to achieve marketing success while ensuring operational productivity in achieving market differentiation.

More Stories

Best Ultralight Hiking Backpacking Tips for Hikers

Organizational Resilience and the Growing Value of Cybersecurity Consulting

How Canada’s Cold Weather Reduces Mining Cooling Costs